Custom graphics collision repair leverages Computer-Aided Design (CAD) tools for precise vehicle restoration and customization. Skilled technicians use CAD to create digital templates, achieve intricate detailing, and represent complex geometry, ensuring accurate visualizations before physical repairs. This method streamlines processes, reduces costs, fosters creativity, and transforms vehicles into unique artistic expressions.

In the realm of custom graphics collision repair, Computer-Aided Design (CAD) tools have emerged as indispensable. This article delves into the intricacies of the CAD process, highlighting its transformative role in achieving design precision. We explore the advantages of adopting CAD technology, from enhancing accuracy to streamlining workflows. By understanding the custom graphics collision repair process and leveraging efficient techniques, professionals can revolutionize their work, ensuring meticulous designs and faster turnaround times.

- Understanding Custom Graphics Collision Repair Process

- Advantages of Using CAD Tools for Design Precision

- Streamlining Workflow: Efficient Techniques and Tips

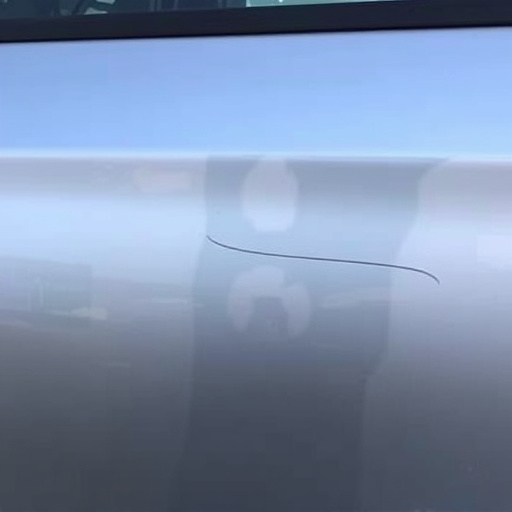

Understanding Custom Graphics Collision Repair Process

The custom graphics collision repair process involves a meticulous series of steps to restore and enhance vehicles with unique and personalized designs. It begins with an in-depth understanding of the client’s vision, which can range from simple customization to intricate graphic overlays. Skilled technicians then assess the vehicle’s damage, employing advanced tools like CAD (Computer-Aided Design) software to map out the repair and design process accurately. This digital approach ensures precise measurements and facilitates the creation of custom templates for frame straightening, a critical aspect in achieving flawless results.

By integrating CAD tools into their workflow, collision repair specialists can offer more than just conventional car paint services. They can create and modify graphics, ensuring seamless integration with the vehicle’s exterior. This level of customization demands attention to detail, precision, and a deep understanding of both automotive mechanics and design principles. The process encompasses not only repairing dents and damage but also enhancing aesthetics, making each restored vehicle one-of-a-kind.

Advantages of Using CAD Tools for Design Precision

Using CAD tools for custom graphics collision repair brings a multitude of advantages that significantly enhance design precision. These digital design platforms allow for meticulous detailing and complex geometry representation, ensuring accurate visualization of the final product before any physical work begins. This level of precision is particularly crucial in custom graphics collision repair, where aesthetics matter as much as structural integrity.

Moreover, CAD tools streamline the design process by enabling quick modifications and iterations. This efficiency saves time and reduces costs associated with manual adjustments, making it an invaluable asset for automotive repair services specializing in dent repair or vehicle dent repair. The ability to seamlessly integrate design changes also fosters creativity, allowing professionals to craft unique, tailored solutions for each collision repair project.

Streamlining Workflow: Efficient Techniques and Tips

In the realm of custom graphics collision repair, Computer-Aided Design (CAD) tools play a pivotal role in streamlining workflows and enhancing precision. By leveraging CAD software, professionals can efficiently create digital designs for vehicle body repair and classic car restoration projects. This technology allows for detailed measurements, precise calculations, and accurate representation of the final product, thereby reducing errors and saving time.

Efficient techniques include utilizing parametric modeling to facilitate quick modifications and iterations, ensuring every detail aligns perfectly with the customer’s vision. Tips for maximizing CAD tools’ potential involve regularly updating software to access new features, collaborating with peers to share designs, and consistently backing up digital files. These practices not only simplify complex tasks in automotive repair but also foster creativity, making custom graphics collision repair a true art form.

Custom graphics collision repair demands precision and efficiency, making CAD tools indispensable. By streamlining the design process, these tools offer unparalleled accuracy and speed, enhancing the overall quality of repairs. Embracing CAD technology not only benefits collision repair shops but also ensures satisfying outcomes for clients seeking tailored, visually impeccable vehicle restyling.